Heat Tolerant

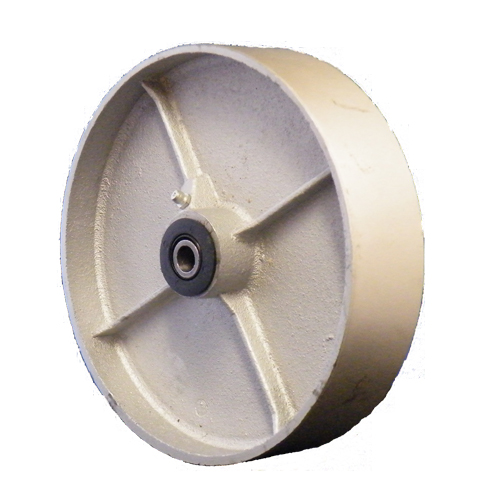

Wheel; 12" x 4"; V-Groove (1-3/4) Ductile Steel; Plain bore; 1" Bore; 4-1/2" Hub Length; 8000# (Item #87306)

$1,054.17

Wheel; 12" x 4"; V-Groove (1-3/4) Ductile Steel; Plain bore; 1" Bore; 4-1/2" Hub Length; 8000#... more info

Caster; Swivel; 6" x 3"; Ductile Steel; Plate (5-1/4"x7-1/4"; holes: 3-3/8"x5-1/4" slots to 4-1/8"x6-1/8"); Bronze Spanner; 6000#; High Temp; Kingpinless (Item #63193)

$283.91

Caster; Swivel; 6" x 3"; Ductile Steel; Plate (5-1/4"x7-1/4"; holes: 3-3/8"x5-1/4" slots to 4-1/8"x6-1/8"); Bronze Spanner; 6000#; High Temp; Kingpinless... more info

Wheel; 6" x 2"; Glass/ Nylon; Hi-Temp (BR); Plain bore; 1200#; 1/2" Bore; 2-3/16" Hub Length; High Temp (425/ 480 deg moist) (Item #87264)

$28.07

Wheel; 6" x 2"; Glass/ Nylon; Hi-Temp (BR); Plain bore; 1200#; 1/2" Bore; 2-3/16" Hub Length; High Temp (425/ 480 deg moist)... more info

Caster; Rigid; 4" x 2"; Cast Iron; Plate; 4"x4-1/2"; holes: 2-5/8"x3-5/8" (slotted to 3"x3"); 3/8" bolt; Zinc; Roller Brng; 900#, High-Temp (Item #63943)

$20.17

Caster; Rigid; 4" x 2"; Cast Iron; Plate; 4"x4-1/2"; holes: 2-5/8"x3-5/8" (slotted to 3"x3"); 3/8" bolt; Zinc; Roller Brng; 900#, High-Temp... more info

Caster; Rigid; 5" x 2"; V-Groove Cast Iron; Plate; 4"x4-1/2"; holes: 2-5/8"x3-5/8" (slotted to 3"x3"); 3/8" bolt; Zinc; Roller Brng; 900#; High Heat (Item #63311)

$33.16

Caster; Rigid; 5" x 2"; V-Groove Cast Iron; Plate; 4"x4-1/2"; holes: 2-5/8"x3-5/8" (slotted to 3"x3"); 3/8" bolt; Zinc; Roller Brng; 900#; High Heat... more info

Caster; Rigid; 8" x 2"; Cast Iron; Plate; 4"x4-1/2"; holes: 2-5/8"x3-5/8" (slot to 3"x3"); 3/8" bolt; Zinc; Roller Brng; Wgt Cap: 900#; Hi-Temp to 800 deg (Item #67674)

$34.21

Caster; Rigid; 8" x 2"; Cast Iron; Plate; 4"x4-1/2"; holes: 2-5/8"x3-5/8" (slot to 3"x3"); 3/8" bolt; Zinc; Roller Brng; Wgt Cap: 900#; Hi-Temp to 800 deg... more info

Wheel; 4" x 2"; Cast Iron; Roller Brng; 3/4" Bore; 2-7/16" Hub Length; 700#; All Steel Components for high heat (Item #88085)

$14.14

Wheel; 4" x 2"; Cast Iron; Roller Brng; 3/4" Bore; 2-7/16" Hub Length; 700#; All Steel Components for high heat... more info

Wheel; 6" x 2"; Glass/ Nylon; Hi-Temp (BR); Plain bore; 1200#; 3/4" Bore; 2-3/16" Hub Length; High Temp (425/ 480 deg moist) (Item #89458)

$24.99

Wheel; 6" x 2"; Glass/ Nylon; Hi-Temp (BR); Plain bore; 1200#; 3/4" Bore; 2-3/16" Hub Length; High Temp (425/ 480 deg moist)... more info

Wheel; 4" x 1-1/4"; Glass/ Nylon Hi-Temp (BR); Top Hat Spanner; 3/8" Bore; 1-3/8" Hub Length; 300#; High Temp Moist (-45 to 425 deg) (Item #88538)

$12.38

Wheel; 4" x 1-1/4"; Glass/ Nylon Hi-Temp (BR); Top Hat Spanner; 3/8" Bore; 1-3/8" Hub Length; 300#; High Temp Moist (-45 to 425 deg)... more info

Wheel; 5" x 1-1/2"; Cast Iron; Roller Brng; 3/4" Bore; 1-7/8" Hub Length; 700#; High Temp (Item #87557)

$14.31

Wheel; 5" x 1-1/2"; Cast Iron; Roller Brng; 3/4" Bore; 1-7/8" Hub Length; 700#; High Temp... more info

Caster; Rigid; 4" x 1-7/16" (5"x1-13/16"); Single Flange Cast Iron; Plate (4-1/2"x6-1/4"; holes: 2-7/16"x4-15/16"); Zinc; Twin 6205 Bearings; 1500#; 600° F (Item #63152)

$54.62

Caster; Rigid; 4" x 1-7/16" (5"x1-13/16"); Single Flange Cast Iron; Plate (4-1/2"x6-1/4"; holes: 2-7/16"x4-15/16"); Zinc; Twin 6205 Bearings; 1500#; 600° F... more info

Caster; Swivel; 4" x 1-1/4"; Glass/ Nylon Hi-Temp; Plate: 4"x4-1/2": holes: 2-5/8"x3-5/8" slotted to 3"x3"; 3/8" bolt; Zinc; 300#; Max 425 degrees (Item #65122)

$20.24

Caster; Swivel; 4" x 1-1/4"; Glass/ Nylon Hi-Temp; Plate: 4"x4-1/2": holes: 2-5/8"x3-5/8" slotted to 3"x3"; 3/8" bolt; Zinc; 300#; Max 425 degrees... more info

Wheel; 6" x 2"; Phenolic; High Temp (BR); Roller Brng; 900#; 3/4" Bore; 2-3/16" Hub Length; High Temp (475/ 550 deg dry) (Item #89454)

$53.02

Wheel; 6" x 2"; Phenolic; High Temp (BR); Roller Brng; 900#; 3/4" Bore; 2-3/16" Hub Length; High Temp (475/ 550 deg dry)... more info

Caster; Rigid; 5" x 2"; Cast Iron; Top Plate; 4"x4-1/2"; hole spacing: 2-5/8x3-5/8 (slotted to 3x3); 3/8 bolt; Zinc; Roller Brng; 800#; High-Temp (Item #65381)

$22.66

Caster; Rigid; 5" x 2"; Cast Iron; Top Plate; 4"x4-1/2"; hole spacing: 2-5/8x3-5/8 (slotted to 3x3); 3/8 bolt; Zinc; Roller Brng; 800#; High-Temp... more info

Caster; Rigid; 4" x 2"; V-Groove (7/8) Ductile Steel; Plate (4"x4-1/2"; holes: 2-5/8"x3-5/8" slots to 3"x3"; 3/8" bolt); Zinc; Roller Brng; 1250#; High Temp (Item #67954)

$31.46

Caster; Rigid; 4" x 2"; V-Groove (7/8) Ductile Steel; Plate (4"x4-1/2"; holes: 2-5/8"x3-5/8" slots to 3"x3"; 3/8" bolt); Zinc; Roller Brng; 1250#; High Temp... more info

Caster; Rigid; 6" x 1-1/2"; Cast Iron; Plate (4"x4-1/2"; holes: 2-5/8"x3-5/8" slotted to 3"x3"; 3/8" bolt); Zinc; Roller Brng; 700#; Hi Temp to 600 deg. (Item #65906)

$17.53

Caster; Rigid; 6" x 1-1/2"; Cast Iron; Plate (4"x4-1/2"; holes: 2-5/8"x3-5/8" slotted to 3"x3"; 3/8" bolt); Zinc; Roller Brng; 700#; Hi Temp to 600 deg.... more info

Caster; Swivel; 5" x 2"; Phenolic; High Temp (BR); Plate; 4"x4-1/2"; holes: 2-5/8"x3-5/8" (slots to 3"x3"); 3/8" bolt; Zinc; Roller Brng; 1000#; 475 deg; Brake (Item #64146)

$54.20

Caster; Swivel; 5" x 2"; Phenolic; High Temp (BR); Plate; 4"x4-1/2"; holes: 2-5/8"x3-5/8" (slots to 3"x3"); 3/8" bolt; Zinc; Roller Brng; 1000#; 475 deg; Brake... more info

Caster; Rigid; 4" x 2"; V-Groove (7/8) Ductile Steel; Plate (4-1/2"x6-1/4"; holes: 2-7/16"x4-15/16" slots to 3-3/8"x5-1/4"; 1/2" bolt); Zinc; Roller Brng; 1500# (Item #67956)

$37.43

Caster; Rigid; 4" x 2"; V-Groove (7/8) Ductile Steel; Plate (4-1/2"x6-1/4"; holes: 2-7/16"x4-15/16" slots to 3-3/8"x5-1/4"; 1/2" bolt); Zinc; Roller Brng; 1500#... more info

High Heat Casters

High heat casters, also known as heat resistant casters, are made for top performance in high-temperature conditions. High temp phenolic and other industrial casters fall into this category. High temperature casters are constructed to withstand damage or melting at a variety of temperatures (depending on the material used to manufacture them), often ranging from 100°C to more than 1000°C. These casters facilitate the movement of heavy trays or racks into and out of extremely hot environments and are frequently employed in setups involving ovens or furnaces.

Key Features of High Temp Casters

High temp casters can withstand extreme temperatures that would cause damage to standard casters. High-temperature casters can make moving heavy items easier, depending on the materials the casters are made of and how they are built. They are sometimes used on steel tracks for this purpose, and some high temp casters offer abrasion resistance. Their applications include the following:

- Foundries - To transport hot metals and alloys from furnaces to casting areas without damaging the wheels. High temp casters used in these applications can withstand temperatures up to 1100°C.

- Steel mills - For moving semi-finished steel products like blooms, billets, and slabs from reheating furnaces to rolling equipment at over 1200°C.

- Aluminum industry - To move hot aluminum products from extrusion/heat treatment ovens. Heat resistant casters used in these environments have to perform well at 400–500°C.

- Metal forging - For handling hot forgings up to 650°C coming out of press machines and transferring to heat treatment stations.

- Plastics industry - Rated for service up to 250°C, used with injection molding machines to wheel off hot plastic parts.

- Glass industry - Glass making equipment like lehrs and kilns rely on casters rated to 500°C for short bursts to transport glassware. Temperature ranges from -50 to +250°C.

To achieve superior heat resistance, specialized materials are utilized in heat resistant casters and associated accessories’ construction. Components like swivel bearings, wheels, and housings are commonly made of solid brass, stainless steel, or cast iron. These metals have high melting points, resisting warping or corroding under extreme heat. Moreover, bushings and ball bearings feature materials like bronze that allow smooth swiveling despite the expansive effects of heat. Additional materials used to manufacture some heat resistant casters include Phenolic; High Temp (BR), Glass/ Nylon; Hi-Temp (BR), and PolyU on PolyO (GY).

In manufacturing high heat casters, the reduction or elimination of joints or gaps where heat damage could occur is important. All components are securely reinforced for maximum load capacity and longevity when continuously subjected to high weights and temperatures. With their heavy-duty builds and reliable performance, customized high temp casters can endure decades of hot industrial use.

Load Capacity and Size Options

Selecting the proper load capacity is crucial when specifying heat resistant casters for industrial applications. Overloading beyond the recommended capacity risks premature wear, failure, and accidents. Heavy duty high temp casters can accommodate extreme loads exceeding several thousand pounds per caster. Applications must be thoroughly evaluated to determine the expected weights of items transported, including peak loads and safety factors. For example, a foundry crucible full of molten metal requires far higher load ratings than an oven rack. The weight rating should include a safety margin to prevent sudden failure from overloads.

Just as critical as the load is matching sizes to usage. Large 10-inch casters easily roll over uneven floors or obstacles but require more storage space. Smaller 2 to 4-inch casters save space yet lack full maneuverability for heavy loads. Swivel casters enable multidirectional movement, while rigid casters travel fixed paths with greater capacity. Whether light-duty or supporting extreme tonnage, heat resistant casters must couple proper load ratings with sizes tailored to operational environments and equipment needs. The wrong choice hampers mobility, while the ideal match enables safe heavy transport even at extreme temperatures.

Heat Resistant Casters Maintenance Requirements

Heat resistant casters used in high temperature environments require regular cleaning and lubrication to prevent wear and ensure smooth rolling motion. Grease and other debris should be cleaned from the wheels and bearings using degreasers or solvents, taking care not to wet any electronic components. Once cleaned, the wheel bearings and axles should be lubricated using high temperature lubricants rated to withstand temperatures exceeding those expected during use, reapplying as needed. Inspect wheels and bearings regularly for signs of wear, cracks, or damage and replace them as necessary. Preventative maintenance helps extend the life of high heat casters in demanding environments.

Quick Email!

Have questions about our products? Wondering what caster would best suit your needs? Just saying hi? Drop us a line here!